Harnessing the Power of Ash and Clay

In the world of primitive technology, where the challenges of the past meet the ingenuity of the present, a remarkable discovery has been made – the creation of a geopolymer cement using nothing more than ash, clay, and a little water. This revolutionary technique, explored by the Primitive Technology enthusiast, offers a glimpse into a sustainable and environmentally-friendly building material that could revolutionize the way we approach construction in the modern era.

Understanding the Geopolymer Cement Process

The key to this remarkable cement lies in the chemical composition of the materials used. The acronym “NASH” – Sodium, Alumina, Silica, and H2O – represents the essential elements required for the formation of a geopolymer cement. These components are all present in the ash and clay used in the experiments, making them the perfect raw materials for this process.

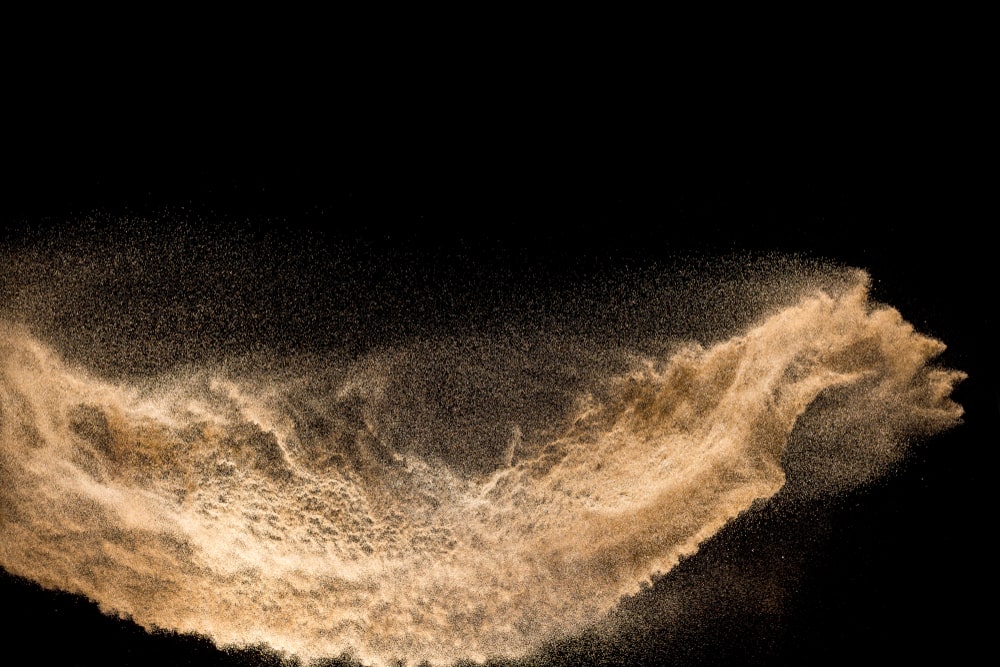

Calcining the Ash

The first step in the cement-making process is to properly calcine the wood ash. By exposing the ash to high temperatures, typically through the use of a forge or furnace, the chemical properties of the ash are transformed, unlocking its cementitious potential. The calcination process is crucial, as uncalcined ash will simply dissolve when exposed to water, rendering it useless for cement production.

Mixing the Ingredients

Once the ash has been properly calcined, it is then mixed with crushed, fired clay or terracotta in various ratios. The experiments conducted have shown that a 1:1 or 1:2 ratio of ash to clay works well, producing a cement that is able to withstand water exposure and maintain its structural integrity.

Rapid Setting and Curing

One of the most remarkable aspects of this primitive geopolymer cement is its rapid setting and curing time. In some cases, the cement was able to withstand water exposure after just 6 hours of curing, a testament to the efficiency of the chemical reactions taking place. This rapid setting time could revolutionize the construction industry, allowing for faster project completion and reduced labor costs.

Scaling Up and Exploring Possibilities

With the successful experiments conducted, the next step is to explore ways to scale up the production of this primitive geopolymer cement. The researcher is considering it as an alternative to traditional brick-making, as the process is potentially simpler and more efficient. This could lead to the development of in-situ formed walls and other innovative building techniques that take advantage of the unique properties of this cement.

Adapting Structures to the New Material

As the use of primitive geopolymer cement becomes more widespread, it will be necessary to adapt the design and construction of structures to accommodate the unique properties of this material. This may involve rethinking traditional building methods and exploring new architectural approaches that maximize the strengths and minimize the potential weaknesses of the cement.

Sustainability and Environmental Impact

One of the most exciting aspects of this primitive geopolymer cement is its potential for sustainability and environmental friendliness. By utilizing readily available natural materials, such as wood ash and clay, the production process has a much lower carbon footprint compared to traditional cement manufacturing. Additionally, the simplicity of the method means that it could be easily adopted by communities around the world, reducing reliance on energy-intensive and resource-depleting industrial processes.

Embracing the Future of Primitive Technology

The development of this primitive geopolymer cement is a testament to the power of human ingenuity and the enduring potential of ancient techniques. By combining the knowledge of the past with the technological advancements of the present, the Primitive Technology enthusiast has unlocked a new frontier in sustainable construction, one that could have far-reaching implications for the way we build and live in the years to come.

As the research and experimentation continue, the possibilities for this primitive geopolymer cement continue to expand. From the construction of innovative structures to the potential for widespread adoption in developing communities, the future of this remarkable material is filled with promise and excitement. By embracing the lessons of the past and the innovations of the present, we can unlock a new era of sustainable and efficient building, paving the way for a more sustainable and resilient future.